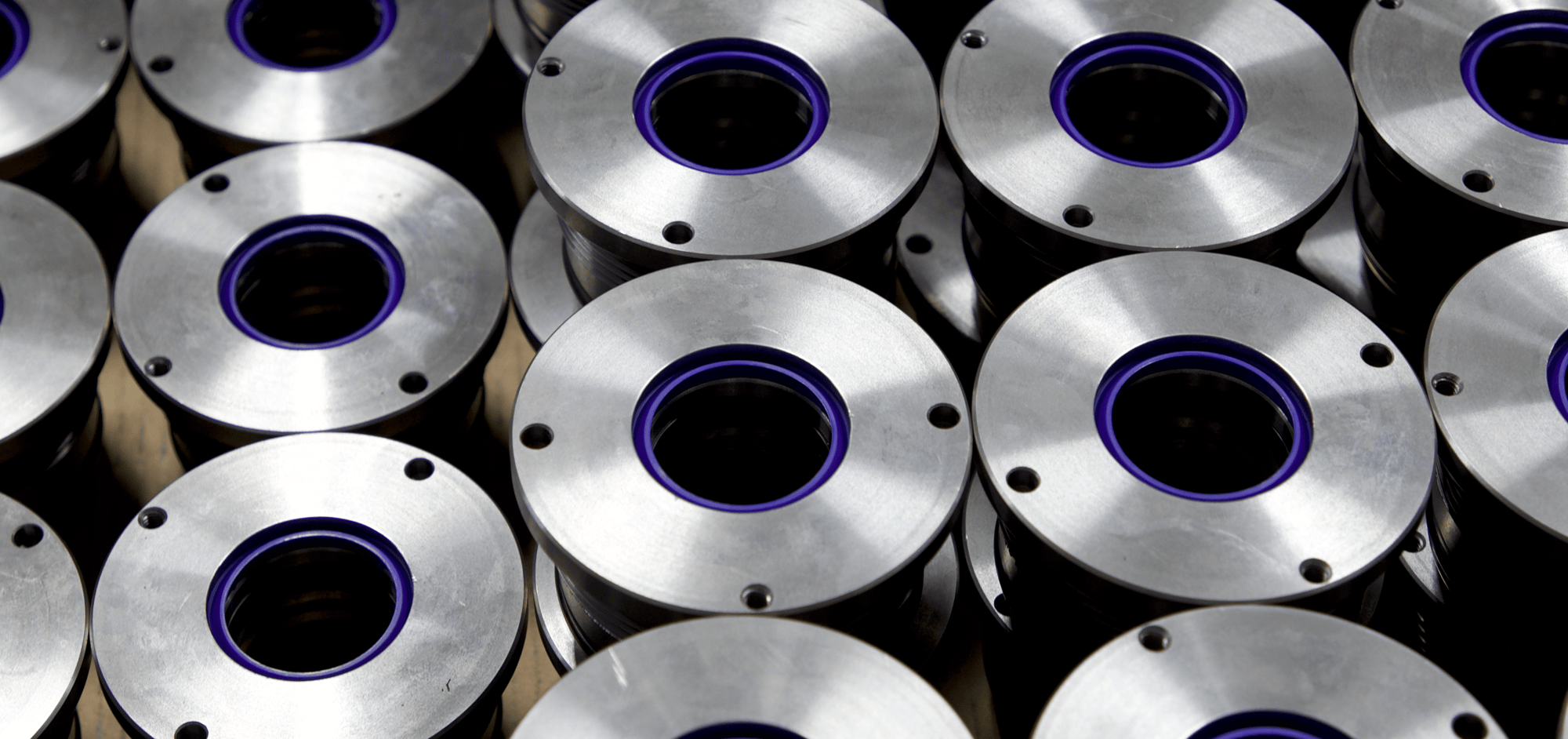

Double Acting Hydraulic Cylinders

Energy Manufacturing custom designs and manufactures 1.5" to 7" bore double-acting hydraulic cylinders to meet the requirements of your application. Standard double-acting hydraulic cylinders accommodate operating pressures up to 5,000 PSI.

These cylinders, including jacks and rams, offer improved speed and efficiency, better movement control, greater versatility, and faster retraction.

Double-acting hydraulic cylinders apply force in both directions in a push-pull motion, allowing for extension and retraction under hydraulic power. They have two ports: one for pressurized fluid to enter and extend the piston, and another for retraction. Their balanced control and consistent force in both directions make them ideal for operations that require high precision.

Double-acting cylinders typically feature seals, rods, and pistons designed to handle high pressures. Their ability to perform work in both directions increases system efficiency.

Markets include:

- Automotive

- Chemical

- General Manufacturing

- Material Handling

- Metals

- Paper & Pulp

Applications include:

- Automobile Transport Carriers

- Conveyor Systems

- Doors

- Furnaces

- Paper Manufacturing Systems

- Powder Coatings Production Systems

Smooth Operation

Heavy Duty Capable

General Features & Specifications

We manufacture double-acting hydraulic cylinders with 1.5” to 7” bore sizes to meet a wide range of application requirements. Built to accommodate operating pressures up to 5,000 PSI, these cylinders are designed for durability, efficiency, and long-lasting performance.

- Lightweight Construction. Our aluminum hydraulic cylinders provide strength without added weight, making them easier to handle and install.

- Dual Action. Hydraulic force is applied in both extension and retraction, ensuring smooth, controlled motion.

- Pressure Rating. Designed to handle moderate hydraulic pressures, ideal for various industrial applications.

- Control. Dual action cylinders offer excellent control for a variety of applications

Custom Double-Acting Hydraulic Cylinders

We offer fully customizable double-acting hydraulic cylinders to meet specific application requirements. Whether optimizing for load handling, pressure ratings, or mounting configurations, our cylinders are engineered for peak performance.

The features we can customize include:

- Bore Size

- Stroke Length

- Rod Diameter

- Port Size and Type

- Mounting Options

- Seal Materials

- Surface Coating

- Cushioning

- Rod End Configurations

- Operating Pressure Rattings

Frequently Asked Questions

Have a question about Double Acting Hydraulic Cylinders? We are here to help.

What are the advantages of double-acting hydraulic cylinders over other cylinder types?

Double-acting hydraulic cylinders offer greater control, efficiency, and versatility compared to single-acting cylinders. By applying hydraulic pressure for both extension and retraction, they provide faster cycle times, smoother operation, and precise force application, making them ideal for applications that require continuous movement in both directions.

How do double-acting hydraulic cylinders function?

These cylinders operate using two hydraulic ports—one for extending the piston and another for retracting it. This bidirectional force application allows for better load control, increased efficiency, and enhanced performance in demanding applications.

What industries commonly use double-acting hydraulic cylinders?

Double-acting hydraulic cylinders are widely used in construction, manufacturing, agriculture, automotive, aerospace, and material handling industries. They are essential in equipment such as presses, lifts, heavy machinery, and automation systems that require precise, controlled motion in both directions.

What are the pressure ratings for double-acting hydraulic cylinders?

Most double-acting hydraulic cylinders are designed to handle up to 3,000 PSI, though some models can be customized for higher-pressure applications based on system requirements.

How do double-acting hydraulic cylinders handle wear and durability?

Double-acting hydraulic cylinders are built with high-strength materials and precision-engineered seals to withstand high loads, repetitive cycles, and demanding environments. Proper maintenance, including regular lubrication and inspection of seals and rods, ensures long-term durability.

Can double-acting hydraulic cylinders operate in high-temperature environments?

Yes, they can be optimized for high-temperature applications by using heat-resistant seals, coatings, and materials that ensure reliability in extreme conditions.

What maintenance is required for double-acting hydraulic cylinders?

Regular maintenance includes inspecting seals, rods, and ports for wear, lubricating to reduce friction, checking fluid levels, and cleaning external components to prevent contamination.

Can double-acting hydraulic cylinders be customized for specific applications?

Yes, double-acting cylinders can be customized with specific stroke lengths, bore sizes, seals, coatings, and mounting options such as clevis, flange, or trunnion mounts. Adjustable cushioning can also be added for better piston control.

Are double-acting hydraulic cylinders suitable for outdoor or corrosive environments?

Yes, they can be designed with corrosion-resistant coatings, anodized finishes, and weatherproof seals, making them ideal for outdoor, marine, and industrial applications.

How do I choose the right seal material for a double-acting hydraulic cylinder?

The right seal depends on fluid type, pressure, and temperature. Viton seals handle high heat and aggressive fluids, Nitrile (Buna-N) seals work well with standard hydraulic fluids, and polyurethane seals provide high-pressure durability.

What are the most common causes of failure in double-acting hydraulic cylinders?

Failures often result from seal wear, fluid leaks, rod or barrel damage, overheating, or exceeding pressure limits. Regular maintenance helps prevent these issues.

What mounting options are available for double-acting hydraulic cylinders?

Mounting options include clevis mounts for pivoting, flange mounts for stability, trunnion mounts for rotational movement, and threaded or spherical rod ends for precise positioning.

Can double-acting hydraulic cylinders be used in heavy-duty applications?

Yes, they are specifically designed for heavy-duty applications where high force and continuous motion are required, such as hydraulic presses, industrial automation, and heavy equipment lifting.

How does the weight of a double-acting hydraulic cylinder impact its application?

Double-acting hydraulic cylinders are engineered to balance strength and weight, ensuring that they deliver maximum force output without unnecessary bulk. This makes them ideal for stationary and mobile equipment where efficiency is a priority.

What are the lead times for custom double-acting hydraulic cylinders?

Lead times depend on design complexity, customization needs, and production schedules. Typically, custom cylinders take a few weeks to several months, so it’s best to consult with the manufacturer for an accurate estimate.

Contact Us

To learn more about how our innovative hydraulic cylinders are made with premium coatings and materials can deliver outstanding performance in highly corrosive environments, provide longer cylinders life, and decrease your maintenance costs, tell us who you are and briefly describe your application.

When you use Energy MFG's field-proven cylinders, you’re getting products and systems that are reliable, rugged and high-performance.