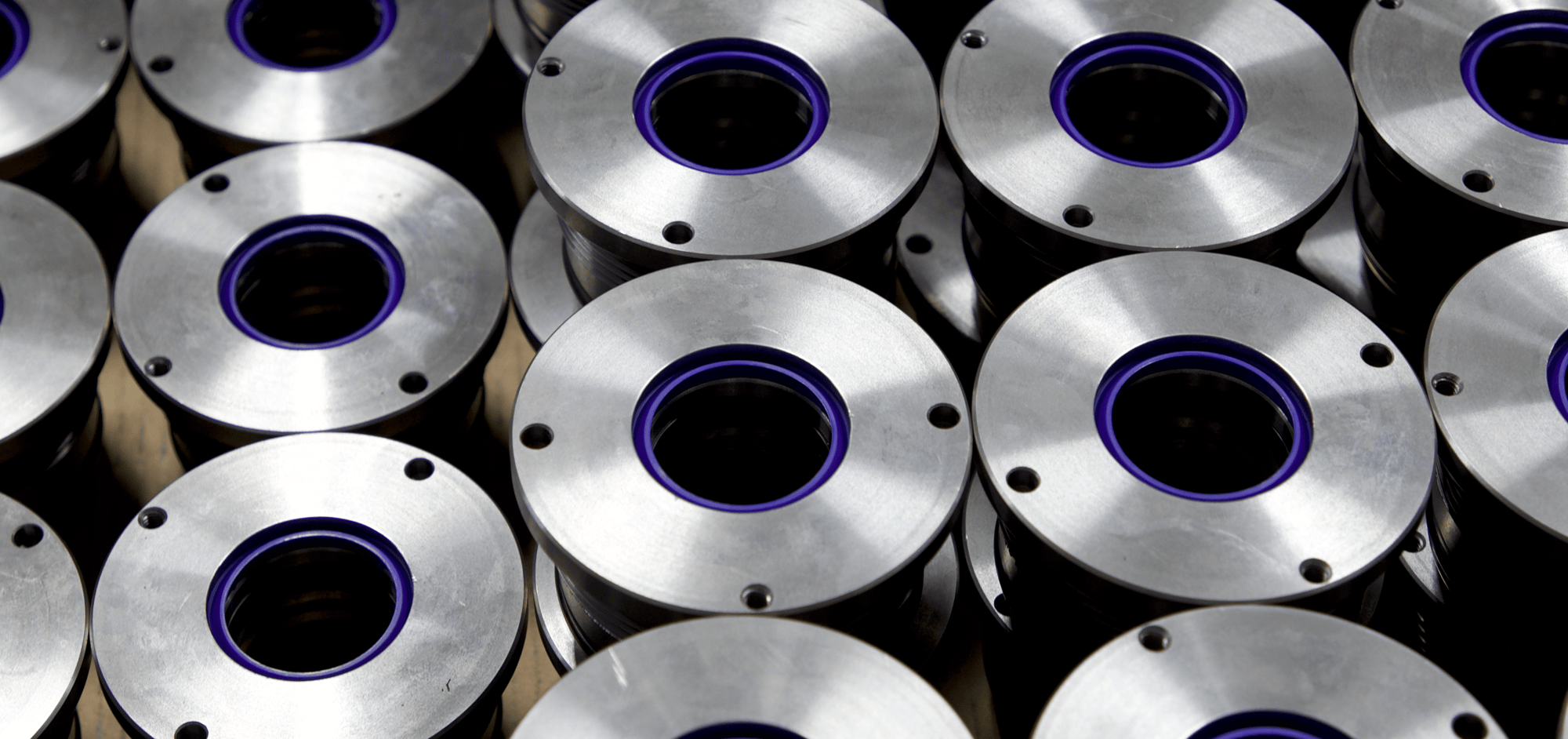

Tie Rod Hydraulic Cylinders

Energy Manufacturing Company designs and manufactures tie rod hydraulic cylinders. These cylinders are commonly used in low pressure applications, up to 3,265 PSI (225 bar) and feature bore sizes ranging from 2” to 4”.

A tie rod hydraulic cylinder is characterized by its construction, using threaded steel rods (tie rods) to secure the end caps to the cylinder barrel. Tie rods act as a fastening system, holding the end caps (baseplate and head) securely to the cylinder barrel to ensure the cylinder’s structural integrity.

The rods are made from high strength steel and can withstand significant pressure and force when used in hydraulic systems to convert fluid pressure into linear motion and provide power to move or actuate components in machinery or equipment.

Markets include:

- Agriculture

- Automotive

- Construction

- Industrial

Applications include:

- Dump Trucks & Garbage Trucks

- Excavators & Loaders

- Material Handling Equipment

- Press Machines

- Sprayers & Balers

- Tractors & Harvesters

Smooth Operation

Ease of Maintenance

General Features & Specifications

Tie rod cylinders are compact and easy to maintain and repair. Their threaded construction allows for quick access to internal components, simplifying maintenance and minimizing downtime.

- Versatile. Tie rod cylinders are typically designed for pressures up to 3,265 PSI (225 bar).

- Strong. Tie rods are made of high strength steel and the cylinder barrel is made from steel. The end caps are made from ductile iron, and the rod is hard chrome plated.

- Flexible. Tie rod configuration is a four-rod design.

- Mountable. Tie rod cylinders from Energy are clevis mounted for pivot applications.

Frequently Asked Questions

Have a question about Hydraulic Cylinder Cushions? We are here to help

What is a tie rod hydraulic cylinder?

A tie rod hydraulic cylinder is a linear actuator that converts hydraulic energy into mechanical motion. It consists of a cylinder barrel, a piston connected to a piston rod, and end caps secured by high-strength threaded steel rods (tie rods). The hydraulic fluid, typically oil, is pressurized to move the piston, generating linear force and motion. This design is especially popular in industrial and manufacturing applications due to its modular construction and ease of maintenance.

What are the advantages of tie rod hydraulic cylinders?

What industries commonly use tie rod hydraulic cylinders?

Tie rod hydraulic cylinders are prevalent in industries like manufacturing (injection molding machines, presses), construction (loaders, excavators), agriculture (tractors, balers), material handling (forklifts, conveyors), and automotive (assembly lines). Their ability to handle high pressures and frequent cycles makes them suitable for both heavy-duty and precision applications.

What are the common sizes and pressure ratings for tie rod cylinders?

How do I select the right tie rod hydraulic cylinder for my application?

-

- Bore size and rod diameter: Determine the force required using the formula Force = Pressure x Area.

- Stroke length: Based on the required linear movement.

- Operating pressure: Ensure compatibility with the hydraulic system's pressure.

- Mounting style: Choose from options like flange, clevis, or foot mounts based on space and load requirements.

- Hydraulic fluid compatibility: Ensure seals and materials are compatible with the hydraulic fluid type (mineral oil, synthetic fluids).

- Environmental conditions: Consider corrosion resistance, temperature extremes, and exposure to contaminants.

What is the difference between a single-acting and double-acting tie rod cylinder?

- Single-acting cylinders use hydraulic pressure to move the piston in one direction, while a spring or external force returns it to the original position. They are used in applications like lifting, where gravity assists in the return stroke.

- Double-acting cylinders use hydraulic pressure to move the piston in both directions, offering better control and efficiency in applications requiring powered extension and retraction, such as presses and machinery automation.

How do I maintain a tie rod hydraulic cylinder?

-

- Inspecting for hydraulic fluid leaks, especially around seals and rod surfaces.

- Checking for rod straightness and surface damage, as scratches can cause seal wear.

- Monitoring hydraulic fluid levels and ensuring the fluid is clean and free from contamination.

- Replacing worn-out seals, bushings, and other components.

- Ensuring the tie rods are properly torqued to prevent end cap loosening.

Can tie rod hydraulic cylinders be repaired?

What types of mounting options are available for tie rod cylinders?

-

- Flange mounts: Provide a rigid and strong connection, ideal for high-force applications.

- Clevis mounts: Allow pivoting, suitable for applications with angular movement.

- Foot mounts: Offer stable support on flat surfaces, commonly used in stationary equipment.

- Trunnion mounts: Enable rotation along the cylinder axis, useful in applications with varying angles. The choice of mount affects the cylinder's alignment, load distribution, and overall performance.

What materials are tie rod hydraulic cylinders made of?

What causes hydraulic cylinder failure?

-

- Contaminated hydraulic fluid: Dirt and debris can cause internal wear and seal damage.

- Seal wear: Over time, seals degrade due to friction, heat, and chemical exposure.

- Rod damage: Scratches, dents, or corrosion on the rod surface can lead to seal failure.

- Improper installation or alignment: Misalignment causes uneven wear and mechanical stress.

- Overloading: Exceeding the cylinder’s pressure or load capacity can cause deformation or failure.

How do I identify the specifications of an existing tie rod cylinder?

Check for the manufacturer’s label or serial number on the cylinder body, which typically lists bore size, stroke, and pressure rating. If the label is missing, measure the bore (internal diameter), rod diameter, and stroke length manually. Identify the mounting style and port configurations to match with standard specifications.

Are tie rod hydraulic cylinders suitable for outdoor use?

Tie rod cylinders can be used outdoors, but they may require additional protection against environmental factors like moisture, dirt, and corrosion. Options include stainless steel components, corrosion-resistant coatings (e.g., epoxy or nickel plating), and weatherproof seals. However, in harsh environments, welded hydraulic cylinders might be preferred due to their sealed construction and better resistance to external contaminants.

What’s the difference between tie rod and welded hydraulic cylinders?

- Tie rod cylinders have a modular design with threaded rods holding the end caps in place, making them easy to disassemble and repair. They are commonly used in industrial applications where maintenance and flexibility are important.

- Welded cylinders have a more compact, welded construction that offers higher strength and durability in rugged environments. They are often used in mobile equipment (e.g., construction and agricultural machinery) where space constraints and exposure to harsh conditions are factors.

Contact Us

To learn more about how our innovative tie rod cylinders are made with quality materials and coatings and deliver outstanding performance in a range of environments, provide longer cylinder life, and decrease your maintenance costs, tell us who you are and briefly describe your application.

When you use Energy Manufacturing Co.’s field-proven cylinders, you’re getting products that are reliable, rugged, and high-performance.